- Automotive

- Innovation

- Solutions

Designing an integrated cooling module for more efficient electric vehicles

Reading time: 3 minutes

Client challenge: Improve the efficiency of an electric vehicle's cooling loop

BEV makers need to find ways to improve the efficiency of their vehicles to increase their range and reduce charging time. A major European OEM challenged Hutchinson to design an integrated module to manage cooling in BEVs, with the goal of increasing the overall efficiency of the vehicle.

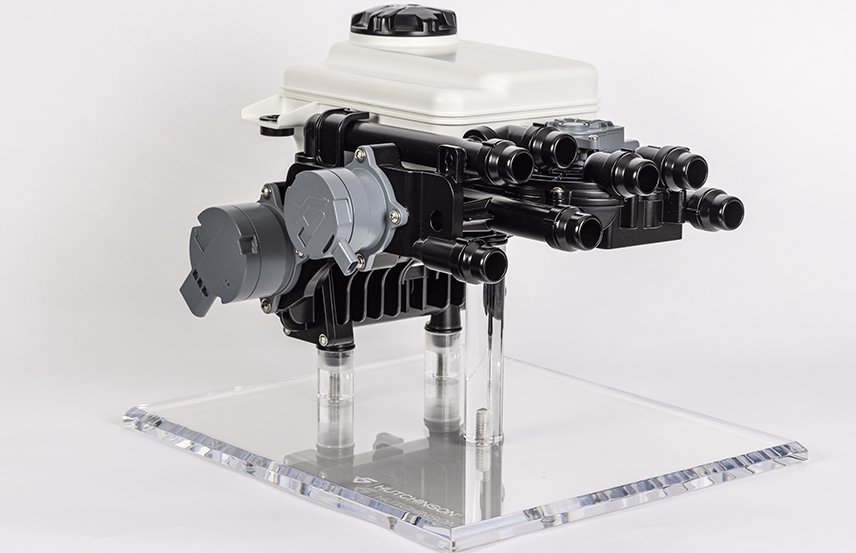

By integrating the pump, valve, expansion tank, and the manifold, could we create a system that used less power, less space, lost less pressure, improved range, and reduced charging times.

Our solution: An integrated cooling module

As a global authority on thermal management systems, we were able to rapidly understand our customer's needs and how the module would have to work.

Drawing together Hutchinson's expertise in valves, internal sealing, plastic injection, and thermal management, we proposed an integrated design that used multi-way valves to reduce power consumption and internal gaskets specifically designed to achieve the challenging specifications of the customer.

Working at our internal simulation and testing facilities, we were able to evaluate different designs and their impact on the energy efficiency and range of the vehicle. Working closely with our customer, we could therefore create a solution that offered the optimum combination of size, weight, efficiency, and power consumption, and validate it in-house to ensure the performance and durability of the solution.

Customer benefits: Better range and performance of complete vehicle

Our integrated cooling module used fewer parts, decreasing the number of connections in the system and reducing the chance of leakage. It also cut down the overall volume of the cooling system, so it required less space, and it was also lighter, helping to extend the range of the vehicle.

Most importantly, it offered improved performance and efficiency, using less power to run the cooling loop and therefore drawing less energy from the vehicle's battery. This also extended the vehicle's range and decreased charging time. Our customer was able to review the efficiency of different approaches at our testing and simulation facilities, enabling them to select the solution that worked best for them.

Results: Faster charging, improved energy efficiency

In tests, Hutchinson's integrated cooling module delivers marked improvements in both vehicle range and charging times:

- In cold conditions, our system was found to improve range by 8%

- Charging time was improved by 12%.

This translates to better performance for OEMs and less range anxiety for end consumers.

Hutchinson's world-leading expertise in thermal management, in addition to parallel expertise in valves, sealing, and plastics, allowed our engineers to design, build, test, and validate a highly advanced solution. The module delivers a win-win for manufacturers of battery electric vehicles, offering improved range and charging times, and reduced volume, without compromising on performance or durability.