- Energies

- Sustainability

- Innovation

- Solutions

Tackling hydrogen power challenges thanks to our sealing and materials expertise

Reading time: 4 minutes

Client challenge: Enhance the reliability of hydrogen electrolyzers, helping to reduce costs of this non-polluting fuel

Hydrogen is an indispensable ally for achieving zero-carbon emission targets in our industrialized societies. Present in very abundant quantities on Earth, it needs to be made available to users with a low environmental footprint, in sufficient volume, and at a competitive cost. However, creating pure hydrogen – most commonly by electrolyzing water into its component elements of hydrogen and oxygen – is a complex and demanding process.

To bring down costs and make hydrogen power competitive with traditional energy sources, we need to improve the production efficiency of electrolyzers, their ability to adapt to power supply fluctuations, and their reliability over 10 years or more of continuous operation. Maximizing these parameters is crucial to guaranteeing optimal production costs for plant operators.

Our solution: Polyolefin elastomer-based seals, custom made to deliver enduring performance

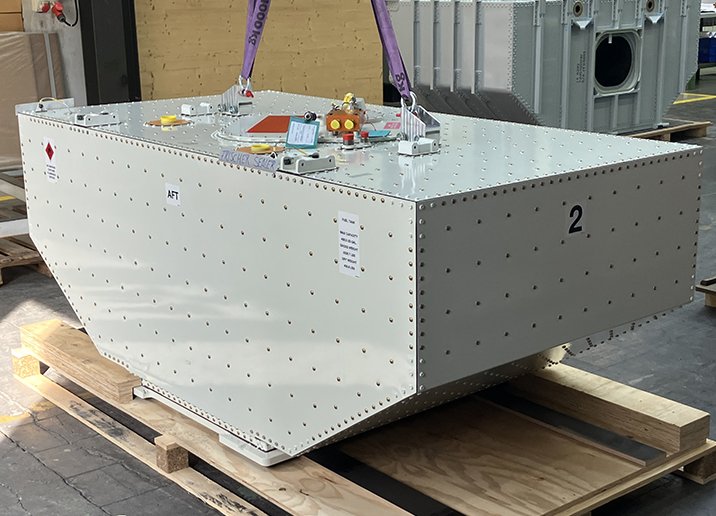

The electrolyzer stack is made up of hundreds of unit cells. To produce a lot of hydrogen, they must have a large active surface area and be able to operate at high pressure and high temperature. The more cells there are, the more powerful the stack. But all fluids in the electrolyzer must be perfectly isolated, and seals have to be robust enough to perform optimally for at least 10 years.

Hutchinson has more than 170 years of experience working with hydrogen, as well as being a world-leader in seals and fluid dynamics. Harnessing our materials expertise, we have formulated polyolefin elastomer-based seals engineered and tested to meet the requirements of Proton Exchange Membrane, Alkaline or Anion Exchange Membrane electrolyzers.

These seals are designed to meet the specific challenges involved in hydrogen production for lifetimes of over 10 years. Our seals operate at temperatures of up to 110°C, at pressures of over 30 bar, and at test pressures of over 50 bar. They can be installed on diameters of more than two meters and can be produced in large quantities to meet the growing demand for stacks of over 300 cells.

Customer benefits: Reliability tailored to the specificities of each plant

Hutchinson's sealing solutions are engineered to perform in the most demanding hydrogen production environments. They do not alter the purity of the water passing through the Proton Exchange Membrane electrolyzers. They also withstand the aggressive pH levels of electrolytes in alkaline electrolyzers, as well as oxidization caused by the oxygen released in the electrolysis process. Hydrogen can easily diffuse through materials, weakening them over time, but Hutchinson's seals are specifically engineered to withstand this kind of aggression.

Hutchinson's products integrate perfectly with our customers' needs, whether that's all-rubber gaskets, or seals bonded to plastic or metal frames, offering the best economic balance at every stage of development. Through rigorous simulation and testing, we're able to optimize product design before creating prototypes. Solutions are tested in our dedicated research centers and in laboratories close to our production sites, in accordance with international standards or specific protocols implemented by our customers, so that we can supply ready-to-use sealing solutions.

Results: More than a decade of solutions deployed in partnership with hydrogen producers

Since 2011, Hutchinson has been supplying electrolyzer stack seals to the hydrogen industry. We are currently involved in several projects aimed at increasing the power of stacks and scaling up production to industrial levels. Hydrogen management requires strict safety measures due to the significant risks associated with gas leaks. Hutchinson mobilizes its aerospace expertise to manage these risks and relies on the operational excellence we have developed for our automotive industry customers to guarantee their control in mass production.

Hutchinson implements eco-design principles and favors raw materials with low environmental impact, thus contributing to the sustainability of the hydrogen produced. What's more, our expertise in the integration of sensors and actuators, as well as in information processing, opens up new possibilities for our customers to optimize the safety and operability of their electrolyzers.

Whatever challenges you're facing in the hydrogen power industry, ask the experts at Hutchinson to create solutions that will take your business to the next level of reliability.